Many years ago I was an FAE for a prominent semiconductor vendor and had the opportunity to understand the design-in process from the vendor’s side. Suffice to say, it’s not easy competing for design-ins when the market is saturated with similar products at various price points. So you may ask, how can a vendor or distributor compete for sockets in a new design project? There are many facets around this dilemma from an FAE or BDM’s perspective.

The first point of decision making is the engineering team and the design engineer who is developing the project. Whether it be a microcontroller, an FPGA or a power electronics component, he or she will have a preference based on previous experience. The best way to overcome their resistance to change, is to offer a component with a significant cost saving. In addition, offer free tools to develop with the part (say if it’s a microcontroller). In fact – go one step further and hand the tools over free of charge. There’s nothing an engineer hates more than having to pay for tools to design in YOUR components. The effort to raise PO’s and get them signed off is annoying. In addition, the rapport that’s built between the FAE and the engineer by not charging for tools, is immense.

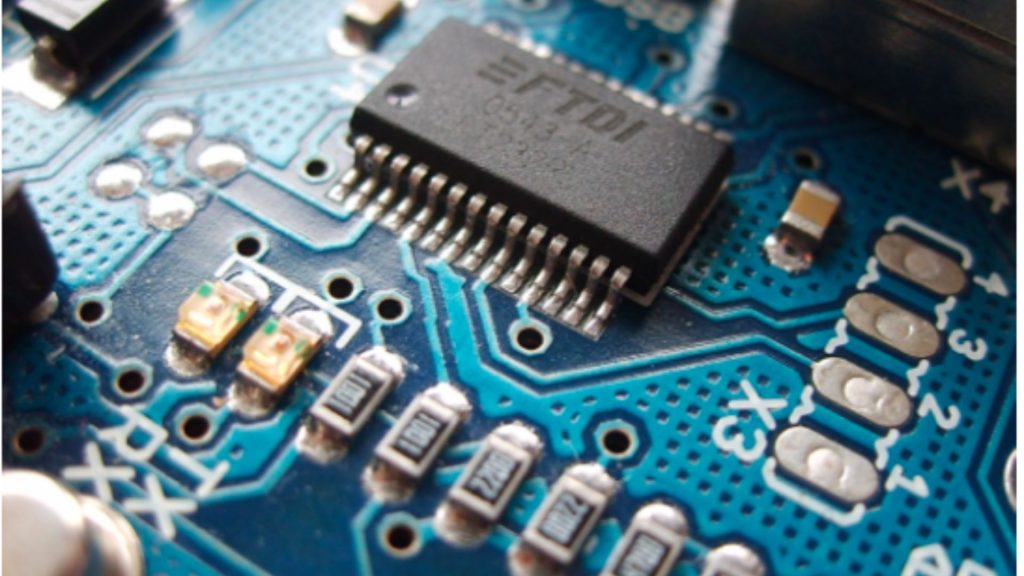

The FAE should visit the client’s site to install them and get them running with the design engineer present. It’s important not to take up any of their time during the installation. Do it whilst they are occupied with their work. Once that’s done, walk them through the operation of the tools using a demo board to demonstrate their use. Make sure the tools are installed on their laptop – the same laptop they take home. The intention is to remove all barriers of resistance to use. In addition, by leaving the tools in a state whereby they are ready to use, an engineer will not be

able to help oneself and will play with the tools and the demo board at some stage. As engineers, that’s how we’re wired. We love trying out new gear.

The other issue that works against a vendor or distributor for a new design-in, is historical preference of one product over another by the client. For instance, if a client uses a particular brand of microcontroller they will inevitably have all the development tools and familiarity with the silicon to leverage rapid design practises. The best way for a vendor to counter this, is to have a good relationship with the customer (the engineers) and look for a new design-in opportunity for a small project. Too often the FAE or BDM will not be focussed on small projects as they don’t offer as much financial reward as a large project, however from a design-in perspective, they present the best opportunity for a new design-in of a microcontroller (say). There are many reasons for this. Firstly a smaller project means the risks are smaller so an engineer may be more willing to try a new family of microcontroller. Secondly, if the new family doesn’t offer the benefits the engineer anticipated, the additional time or expense to complete the project will have minimal impact on timelines so there’s less concern. The downside however is the engineer will usually be a junior team member who may not have the commercial skills to convince his team leader to use a new component. This is where the FAE earns his or her money to assist the engineer to convince the powers-to-be, to make the change.

Another significant way to win design-ins is through exemplary customer service. If an issue is raised, make it a priority to mobilise resources to resolve it. Allow the engineer to talk to the local and overseas technical people one-on-one, so communication and speed of response is greatly improved. Don’t put blockers in place to stop them. This also improves the accuracy of communicating the issue and obtaining a resolution. If the engineer can talk directly to the vendor’s technical specialist at a design centre, he or she will feel the vendor is listening and they will experience a greatly reduced level of frustration. There’s nothing worse than a frustrated engineer and they will remember the frustration next time a new design is allocated to them.

Finally an act of generosity that’s often forgotten. Engineers like to be wined and dined, so instead of taking the purchasing people out for lunch, take the engineers. You will improve the rapport with them, and they probably won’t ask you to order a $300 bottle of wine just because they can!